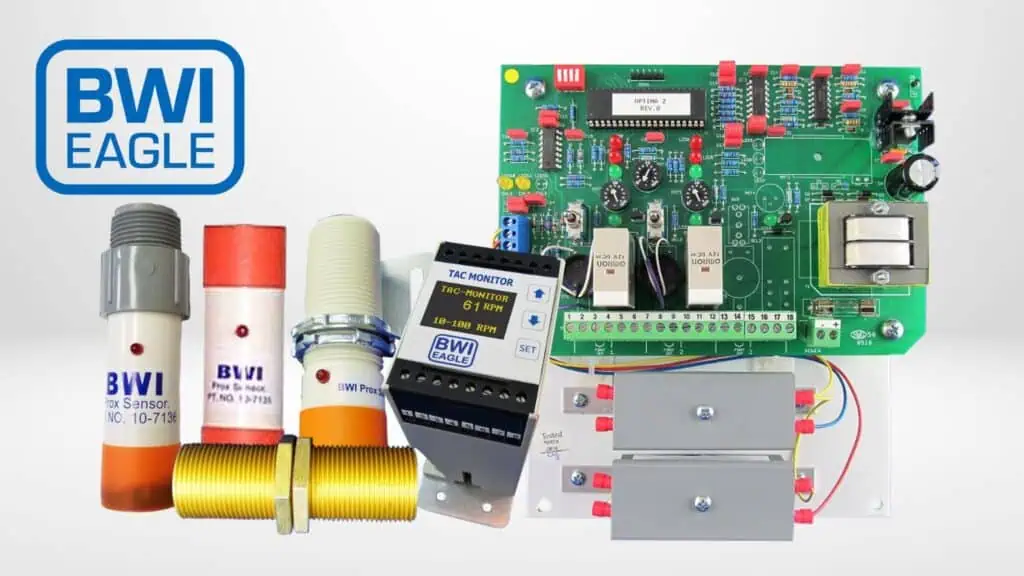

BWI Eagle Speed Switches And Sensors

BWI Eagle speed switches and sensors provide protection for equipment that is easy to install and operate.

BWI Eagle

Speed Switches and Sensors

BWI Eagle digital speed switches and non-contacting proximity sensors monitor the speed and motion of any rotating apparatus. We provide premium protection of expensive conveyor belting and other equipment with our panel, DIN-rail or standalone NEMA-rated speed switches that are easy to install and operate.

Panel and Din Rail Mount

Tac-Switches provide accurate and reliable speed detection for conveyors, crushers and rotating shafts. With a digital display and easy-to-use programming buttons, you can eliminate calibration guesswork and achieve accuracy better than +/- 0.5%. Our Tac-Switches also offer a wide range of speed coverage, from 6 to 3000 RPM, and feature an OLED screen for quick monitoring of belt speed and RPM trip settings. Plus, with a DP/DT relay for direct contact or PLC input, built-in ramp timer and included DIN-rail mounting options, our Tac-Switches are the perfect solution for all your speed detection needs.

NEMA Enclosed

The BWI Eagle speed switches are housed in NEMA-rated enclosures that meet the environmental challenges of standalone installations. Select models speed switches feature a first out indicator to simplify troubleshooting, decrease downtime and get machinery back on the line faster. These switches are ideal for applications requiring multiple channels to monitor both slip and sequence.

Intrinsically Safe

Intrinsic safety is a protection technique for the safe operation of electrical equipment in hazardous areas by limiting the energy, electrical and thermal, available for ignition. Many industrial, chemical and process environments have significant explosion risks due to the presence of methane-air mixtures. Whenever equipment is installed where combustible material is present, it is essential to take steps to minimize the risk of ignition. Intrinsically Safe speed switches and sensors minimize power and heat creation, helping to ensure a safer work environment.

Proportional Speed Monitors

A Tac-Monitor is the perfect solution for converting rotary shaft speed into an analog 4-20mA output. With a digital display and easy-to-use programming buttons, you can eliminate calibration guesswork and achieve accuracy better than +/- 1%. Our Tac-Monitor also offers a wide range of speed coverage, from 10 to 6000 RPM, and features an OLED screen for quick monitoring of belt speed and RPM speed range settings. Plus, with proportional speed and true slip monitoring of variable speed drives, continuous monitoring for zero-speed, under-speed and over-speed applications, a 4-20mA output for direct PLC input, and included DIN-rail and optional mounting plate, our Tac-Monitor is the ultimate solution for your speed conversion needs.

Overspeed Monitors and Decoders

The Overspeed Monitor and Decoder monitor speed and detect motion in conveyors, crushers, fans, motors and other rotating apparatus. It can monitor speed ranges of 30 – 3000 RPMs and includes a user-programmable 5 to 30-second fault timer. The Overspeed Monitor utilizes a non-contacting proximity sensor that may be remotely located up to two miles from the control unit. The control unit conveniently mounts inside an existing electrical panel or OEM control box. The aluminum mounting plate is removable for mounting to a DIN rail. The upfront display conveniently shows the current RPM in real time.

Sensors

BWI Eagle’s non-contacting sensors are designed for reliability in any industrial environment. They are available in Variable Reluctance (VR) and Inductive Proximity (Prox) types in three mounting styles. Completely epoxy sealed with LED indicators and integral MSHA signal cable, BWI Eagle’s sensors are virtually indestructible.