Enhance Safety with Crane Remote Control

Cranes are invaluable to various industries, including construction, manufacturing, warehousing, steel production, grain, logging, ship loading, and rail yards. The reliance on cranes for loading, unloading, and moving heavy materials will remain for the foreseeable future. This necessitates a continued focus on maintaining or improving operational safety and having the proper safety protocols in place.

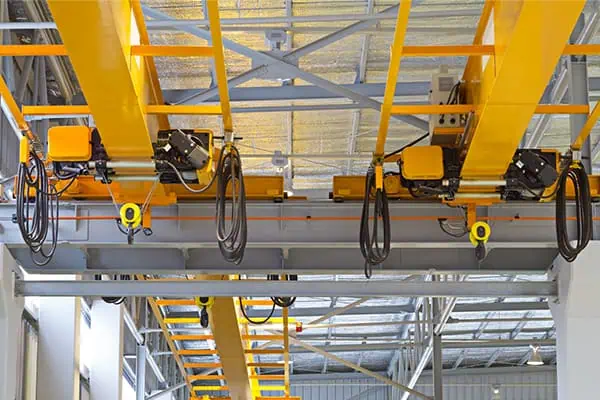

One safety measure that is now widely adopted is using a wireless crane remote control system to control the crane rather than pendant or cab controls. While these systems achieve a variety of process and efficiency improvements, operator safety is a significant driver of their adoption. There are three primary ways crane remote control systems should be a part of every crane operator’s safety manual.

- Minimizing the risk of falling material or dropped loads.

- Reducing the element of human error.

- Identifying trip hazards and pinch points.

Wireless Crane Remote Control Reduces Risk of Falling Material or Dropped Loads

An elevated risk of accidents due to falling materials is present unless the operator can be positioned safely from the load. Additional risk factors include:

- Reduced line of sight to the load

- Trip/slip hazards

- Mechanical failure

- Operator competency

While using a crane remote control, the operator is no longer tethered to the pendant and hence the crane, allowing the operator to position themselves out of the danger zone, away from the hoist and its load.

Compared to the field of view when using a fixed pendant, the remote control offers greater visibility and an expanded line of sight to other operations and personnel on the ground. This enables operators to avoid or alert other work crew members to an impending hazard and prevent it from happening.

Reduce Human Error with a Wireless Crane Remote Control

One of the most critical factors in minimizing accidents is ensuring the crane equipment is operated by qualified workers. Having the proper certification and training on the equipment dramatically improves the operator’s ability to prevent an accident.

Modern wireless remote controls come equipped with built-in safety features to supplement the operators’ knowledge, adding another layer of prevention to the safety plan. Examples of safety features in standard crane remote control systems include:

- Ergonomic design to prevent inadvertent operations.

- Easy to access and safe, machine stop switch.

- Prevention of unexpected motions by using push-to-operate buttons and bars or double-jog-enable features, blocking illogical combinations and applying interlocks and restrictions on certain function combinations.

- Haptic (vibration), LED, and LCD indications and feedback.

- RF and Infrared Close Start, RF Range limiting, and Infrared zoning.

- Key interlocks and supervisory functions.

Identify Trip Hazards and Pinch Points with a Wireless Crane Remote

Crane remote control systems give crane operators additional mobility and improved line of sight. These two factors make it easier for operators to identify potential tripping hazards and pinch points. Operators can move at their own pace rather than the pace of the crane since they are no longer tethered to it.

Additionally, operators are no longer restricted by the range of movement of the pendant, which gives them the flexibility to position themselves at a better vantage point with an improved line of sight, enabling them to plan their movements and reducing the likelihood of tripping/slipping and crush points during the crane operation.

Thankfully, businesses and operators have adopted a wide variety of safety measures to keep crane operators safe and preserve the essential use of cranes in these industries. Using a crane remote control adds another layer of protection and will continue to be used by crane operators for many years.

Find A Crane Remote Control System for You

Our crane control systems come in handheld pushbutton and bellybox styles, offering a wireless experience that makes them easy to operate. Find the perfect crane remote control system for your specific needs by contacting a Cattron representative.